Manual transmissions are a type of gearbox that is slowly becoming a thing of the past, but still remains relevant to the delight of true petrolheads. A manual gearbox is a mechanical gearbox, known in common parlance as a ‘mechanic’. There is a reason for this name, as changing gear requires the driver to engage a complex mechanism.

We have already talked briefly about how car gearboxes are arranged, how they work and what they consist of. Today we are going to tell more about MT – what it is, we are going to analyse the gear box device, we are going to see what the gear box scheme looks like, we are going to find out what it consists of, we are going to determine how often it is necessary to take the car with MT to the service and the main thing – how to prolong the life of this not expensive unit and to make it not break down.

Mechanical transmission: the principle of operation

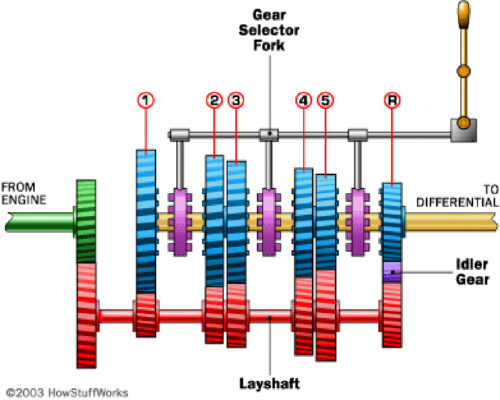

Let us briefly repeat the device of the gearbox “mechanics” in the car. So, what it consists of: it always has an input shaft, which is connected to the engine, and an output shaft, from which the driving wheels of the car are driven.

These shafts are connected by pairs of gears – depending on the number of gears in the gearbox. Each pair has a different ratio of the number of teeth on the gears. This is called the gear ratio and determines how much faster or slower the output shaft will turn than the input shaft. At any given time, the rotation from the engine to the wheels is only transmitted through one of these pairs of gears (gear), while the others rotate freely. And when the car is stationary or rolling freely, all the gears are spinning idly – this mode is called neutral.

The gearbox also has a mechanism that engages and disengages the gears. It is controlled by the driver by moving the gear lever in the cabin, hence another name of the unit – manual gearbox. This mechanism rigidly connects this or that pair of gears with shafts, using a system of rods, clutches, locking gears on the shaft and synchronisers, which makes the process of shifting smoother.

All the parts described are partially immersed in a special gearbox oil which lubricates (and cools) the gears, clutches and shaft bearings. To prevent this oil from leaking out of the unit, it is sealed by gaskets at the joints and by glands at the shaft exits.

Finally, there is the clutch, a pair of coaxial discs that connect the gearbox to the engine flywheel. When the driver “depresses” the clutch, the discs rotate independently. But as the driver releases the left pedal, the clutch discs are pressed closer and closer together by powerful springs – and eventually begin to rotate as a unit, transferring engine power to the gearbox and on to the wheels.

Complicated? Sure. But compared to other transmissions, this one is the simplest. So it is not unreasonable to consider it the most reliable. The MT is organised in such a way that, unlike other gearboxes, it has no electronics or hydraulics that require precision parts. The downside of this simplicity is that there is virtually no ‘foolproofing’ built into the gearbox. As a result, a rash action can render a previously perfectly serviceable unit inoperable. Finally, another characteristic of “mechanics” is that it often does not give any obvious signals of its ailments, working, as the saying goes, until the very end. Because of what an inexperienced driver can do in a moment, a car can only move on a tow or a tow truck.

| Popular posts |

|---|

| What to do to prolong the life of your manual gearbox |

| Automatic transmission: what it is, how it works |

How to drive correctly with a mechanical gearbox

Most gearbox problems are caused by the driver himself – by his clumsy actions. Observe and analyse your driving style in all its phases and try to understand if you are doing everything right? To keep your gearbox working for a long time and to prevent wear and tear on its parts, it is enough to follow some very simple rules.

- When changing gear, always keep the clutch pedal fully depressed. Motorsport drivers may have other methods, but their aims are different and far from extending the life of the car’s gearbox. In our case, there is no such thing as “half-pressing” – any grinding or other teeth-crunching noise during shifting means that the gears are literally hitting each other and destroying each other at the same time. At such moments, curse yourself, not the “iron”.

- The engagement of each gear is done by a smooth and easy movement of the lever. The structure of the gearbox is such that an insufficient effort to drive the lever into an invisible “puddle” will lead to premature loosening of the whole mechanism. And if the gearbox constantly resists your efforts – take it in for servicing: it should not be like this.

- The gear should be disengaged in the same way, never forgetting to push the clutch all the way in. At this point there is an opening in the clutch plates. This removes the load from the gears and clutches, including the braking force generated when the accelerator is released.

- When engaging the next gear, release the clutch smoothly. Too fast a throw of the pedal will provoke a sharp increase in the load on all parts of the gearbox, with the risk of their destruction. And in the inevitable gaps for any mechanism (for example, between the teeth of the gears) such a jump will turn into shocks, also destroying the structure.

- The actions in the previous paragraphs should not become too long a process. If the clutch plates close together too smoothly, they will slip relative to each other for a long time – and thus wear out intensively. The clutch is said to “stick”. And the longer the clutch plates are completely disengaged, the greater the load on the clutch control mechanism. Its safety margin is not infinite.

- For the same reason, you should not roll or stand still with the clutch pedal depressed for a long time. But do not forget that in order to reduce the time taken to operate the pedal and lever, it is important to be clear about the order of their actions. If you do not achieve clarity and synchronisation in all movements, the synchroniser box, clutches and fork shifting mechanism will suffer when shifting.

- When riding in a gear, do not leave your foot on the clutch pedal as a comfortable cushion. Break this habit if you notice it behind you. Even light, imperceptible pressure on the left pedal in a car can cause the clutch plates to slip, heat up and wear quickly.

- Do not engage reverse until the car has come to a complete stop. It is designed to engage when the wheels and transmission output shaft are stationary. Therefore, reverse gear does not normally have a synchroniser – and attempting to engage reverse will inevitably result in a shock to the transmission.

How to extend the life of a MT

Manual gearboxes, like all other types of gearboxes, will last longer if they are used in a gentle manner, without extreme and extraordinary loads. Here are a few tips to maximise the life of the unit.

Try to drive in the optimum gear

This is a simple and seemingly obvious rule that many people neglect. It is not only good for the engine, for which the “mechanics” make five, six or even seven gears, but also for the gearbox itself.

In town, high gears are not recommended

Firstly, you always need a reserve of traction for acceleration. And secondly, low revs can cause jolts in the engine which, as we have already seen, can be detrimental to the box.

On the motorway, the rule is simplified: use higher gears for smooth driving, but shift down in advance for overtaking.

Avoid shifting unnecessarily at revs close to the red zone of the rev counter

When driving dynamically, riders with mechanical transmissions tend to shift up to maximise engine power. However, the higher the rpm at which the next gear is engaged in the gearbox, the greater the bounce when changing gear. This means that the “jerk” loads on the gears, synchronisers and, most importantly, the clutch increase.

Shift down in time

If it is not necessary to shift down for overtaking, when maximum engine power is required, but simply to reduce the speed of the overall flow, it is not sensible to go through all the stages of the gearbox in reverse order. When the accelerator is released at each stage, the wheels are forced to rotate the engine, simultaneously loading the gearbox and clutch gears. As long as the engine’s traction is not needed, you can let the revs drop to almost idle. As soon as traction is required again, immediately shift into the gear required for adequate acceleration.

Do not downshift if the engine is already revving above average

Remember the rpm spike when you shift up late? The same thing will happen here, but in the opposite direction: the engine will rev up sharply and may even exceed the maximum rev limit. This is another blow to the gearbox and clutch. For the same reason, it is better not to use the engine brake in all cases where it makes no sense. And on mountain roads, before a long descent, downshift after reducing speed, not when the car starts to gain ground.

In winter, do not park the car and leave it in gear

The mechanism is designed so that the clutch and synchroniser can “stick” to the gear when the oil thickens in severe frost. And even after the lever has been moved to the neutral position, starting the engine is accompanied by a sudden jolt of the car – which is transmitted to the wheels by frozen parts of the gearbox.

Allow the transmission to warm up

After a long period in the cold, the oil in the gearbox does not warm up as quickly as in the engine. Also, in a manual gearbox, the oil is not delivered to the components and parts under pressure, but is splashed onto the unit by the rotating gears. Understandably, solidified oil makes this worse. It is therefore not necessary to stress the “mechanics” during the first few kilometres. Sometimes you can tell the degree of warming up by the force with which you engage the gears – due to the viscous oil and the “tightness” of the lever.

In very hot weather, stick to the minimum number of gear changes

Apart from the fact that the oil is already too liquid, which is particularly harmful to the gears, every time you change gear you will inevitably slip the clutch. This causes the plates to heat up and the parts around them to heat up, including the gearbox.

How to care for your manual gearbox

As well as working properly, a manual gearbox, like any complex piece of equipment, needs maintenance and regular checks. Even when it’s working perfectly.

Check for oil leaks from the gearbox

Lubricant leaks from a modern gearbox are rare, but they are the most dangerous of all hazards. To check, just look at the tarmac and see if there are any dark oil stains on it after parking.

Check the level and condition of the gearbox oil at least once a year

If the gearbox does not have a special dipstick like the engine, the oil level is usually checked by unscrewing the filler plug. The oil should be at the bottom of the plug. And if you look closely, it should be free of shiny particles such as metal dust or shavings from worn parts. If you are forced to top up, do not use lubricants other than those that come in the box.

Change the oil

Although many gearboxes are now declared “maintenance-free” for their entire life (allowing the owner to sleep soundly during the 100-120 thousand kilometre warranty period), it is better to have the oil completely changed at the “mechanic” at least once every 60-75 thousand kilometres. Moreover, this procedure is quite simple and the grease for the gearbox is cheaper than for other gearboxes.

This also applies to the gear selection mechanism

Leaks and jams in the rod or cable system do not threaten the gearbox itself. But they can cause more trouble: you are simply left with a car in which none of the gears are engaged.

Note any changes in the way the gearbox operates

The appearance of noises or vibrations in any operating mode (while driving, in “neutral”, with the clutch depressed, during shifting, etc.) – a reason to contact a specialist. Difficulty or inability to engage any gear, as well as spontaneous disengagement, is a sure sign of malfunction.

Modern manual gearboxes can easily last several hundred thousand kilometres

And some can outlive the car itself. But, we repeat, only if the gearbox is operated correctly. Otherwise, technical problems can occur even during the warranty period.

Summary

- Mechanical gearbox consists of shafts, pairs of gears (according to the number of gears), clutches, gear engagement mechanism, clutch discs and synchronizers.

- How many shafts are in the box? At least two, primary and secondary. But for layout reasons, intermediate shafts can be added.

- Mechanical gearbox is the simplest and most unpretentious box, but to make it last long, you need to follow simple recommendations.

- Try to avoid jerks and shocks in the transmission, correctly choosing the moment of changing gears.

- Manage the clutch pedals, gas pedal pedals and gearshift lever with care. Develop automaticity in handling them by coordinated action with your feet and right hand.

- Do not downshift at excessively high engine speeds or attempt to accelerate from too low an engine speed. Eliminate all other out-of-range modes.

- Service the gearbox correctly and in a timely manner.

- Maintain the serviceability of the associated controls (clutch, shift actuator).

- Do not ignore the signs of malfunction of the gearbox

What Color Should Transmission Fluid Be?